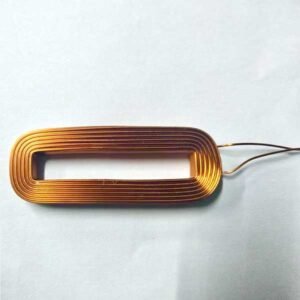

Copper coil windings are the core components that determine the performance of axial flux generators. However, many customers face two major challenges when sourcing coils:

- Off-the-shelf coil products fail to meet the specific requirements of their equipment, leading to inefficiencies.

- Customized coil production often involves long lead times and inconsistent quality, affecting project timelines and equipment performance.

As a professional coil manufacturer, Zhihong Coils provides fast, efficient, and reliable customized solutions to address these pain points and help customers achieve their goals.

Customer Challenge 1: Standard Coils Fail to Fit Specific Equipment

Many customers report that standard coils in the market often fall short of meeting the unique demands of axial flux generators. These generators require specialized coil designs due to their unique magnetic flux paths and operating frequencies. Using mismatched coils can result in:

- Low Magnetic Flux Coupling Efficiency: Leading to increased energy losses and reduced power output.

- Size Mismatch: Making installation difficult or even impossible, disrupting the overall equipment structure.

- Insufficient Thermal Stability: Resulting in overheating or insulation failure during operation.

Zhihong Coils’ Solution:

- Tailored winding designs based on specific equipment parameters (e.g., power, frequency, dimensions) to ensure seamless compatibility.

- Optimized coil turn count, wire gauge, and winding layout to enhance magnetic flux coupling efficiency and significantly improve generator performance.

- High-quality enameled copper wires and high-temperature insulation materials to ensure long-term stability under heavy load conditions.

Customer Challenge 2: Long Lead Times and Inconsistent Quality in Custom Production

In addition to compatibility issues, customers are often frustrated by the long production cycles and quality inconsistencies of customized coils. When projects are time-sensitive, delays or substandard products can lead to significant setbacks or equipment malfunctions.

Zhihong Coils’ Solution:

- Efficient Production: Equipped with 35 high-precision winding machines, we respond quickly to customer demands, delivering high-quality products in a short timeframe.

- Rigorous Quality Control: Adhering to ISO quality management systems, we perform comprehensive tests on electrical conductivity, thermal performance, and mechanical strength to ensure each product meets customer standards.

- Flexible Order Handling: Whether for small-batch prototypes or large-scale production, we efficiently fulfill orders to meet project deadlines.

Success Story: From Custom Design to Delivery

A wind power equipment manufacturer approached us with two primary concerns:

- Designing a winding solution perfectly tailored to their axial flux generator.

- Completing bulk production and delivery within two weeks.

Our Solution:

- We redesigned the winding structure based on the customer’s equipment specifications, optimizing magnetic flux coupling efficiency and using high-temperature materials to address thermal management issues.

- Leveraging high-precision winding machines, we accelerated production and ensured consistent quality.

Results:

- The generator’s efficiency increased by 20%, and operating temperatures dropped by 15%.

- The customized coils were delivered one day ahead of schedule, enabling the customer to complete their project successfully.

Why Choose Zhihong Coils?

With professional technical team,high-precision equipment and strict quality management system, Zhihong Coils has become a trustworthy partner of customers:

- Customization Expertise: Tailored solutions ensure that coils perfectly match equipment requirements.

- Fast Delivery: Quick response and shorter production cycles save valuable time.

- Reliable Quality: From material selection to final testing, every step is carefully monitored to deliver durable, high-performance coils.

If your project faces similar challenges, we are ready to provide professional support. Contact us now for a free consultation or a tailored solution!

Need a customized coil?

Email us for a quick contact

Relative Product