Electromagnetic coils are at the core of modern technology, from powering electric motors to enabling wireless communication. Understanding the key factors that influence their performance and application is crucial for engineers, manufacturers, and tech enthusiasts alike. This blog highlights the 10 most important factors about electromagnetic coils you should never overlook.

Table of Contents

Material Matters: The Core of Coil Efficiency

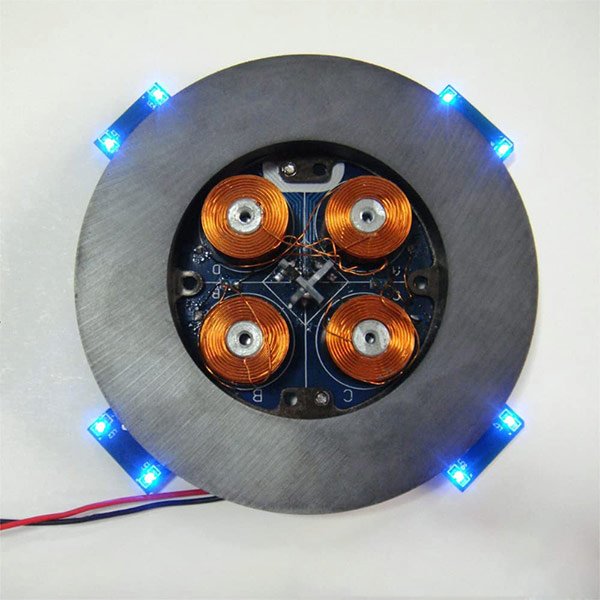

The material used for the coil and its core significantly impacts efficiency. High-conductivity materials like copper and aluminum are preferred for the windings, while cores made from soft iron or ferrites enhance magnetic performance.

Turns Count: The Power of Precision Winding

The number of turns in a coil directly affects its inductance and magnetic field strength. Precise winding ensures the coil meets the required specifications for different applications.

Frequency Compatibility

Electromagnetic coils operate differently at high and low frequencies. Air-core coils are better suited for high-frequency circuits, while iron-core coils excel in low-frequency applications like transformers and motors.

Size and Shape: Not One Size Fits All

The physical dimensions and geometry of a coil influence its magnetic field distribution and thermal performance. Custom shapes, like flat copper coil or toroidal coils , cater to specific design requirements.

Insulation and Coating: Protecting the Coil

Proper insulation prevents short circuits and ensures long-term reliability. Specialized coatings, such as enamel or varnish, protect coils from environmental factors like heat and moisture.

Heat Management: Preventing Overheating

Overheating can degrade coil performance and reduce lifespan. Effective thermal management, including proper spacing and the use of heat-resistant materials, is critical in high-power applications.

Customization: Tailored for Every Application

From self-bonding coils to high-precision motor coils, customization is essential for meeting diverse industrial needs. A tailored design maximizes efficiency and minimizes waste.

Durability and Testing

High-quality coils undergo rigorous testing to ensure durability and compliance with industry standards. This is especially important in medical, automotive, and aerospace applications.

Environmental Factors: Where Will the Coil Operate?

Environmental conditions like temperature, humidity, and vibration affect coil performance. Selecting materials and designs that withstand specific conditions ensures reliability in challenging environments.

Industry Trends: Staying Ahead of Innovation

Emerging technologies like wireless power transfer, superconducting materials, and AI-driven coil design are reshaping the electromagnetic coil industry. Staying informed about these trends helps you stay competitive.

Conclusion

Electromagnetic coils are more than just components; they are the backbone of countless technologies. By understanding these 10 critical factors, you can design, select, or manufacture coils that deliver exceptional performance and reliability.

Whether you’re a manufacturer seeking optimized designs or a buyer looking for quality products, keeping these factors in mind will ensure success. Don’t ignore them—your project’s success might depend on it!

Need a customized coil?

Email us for a quick contact