Coil winding is the process of wrapping wire around a core to create a coil. These coils are essential parts of many electrical devices like motors, transformers, and inductors. The design of the coil and the winding technique used depend on the specific needs of the application.

Key factors to consider when choosing a coil winding method include:

- Coil Shape and Size: The coil needs to fit the available space in the device.

- Electrical Requirements: The coil must handle the voltage, current, and heat in the system.

- Magnetic Field Strength: The coil should produce the necessary magnetic field for its function.

- Insulation: Proper insulation is needed to protect the coil from damage.

- Space and Position: The coil’s location within the device can affect the design.

In this article, we’ll cover the different types of coil winding techniques and their uses in various applications.

Why Coil Winding Matters

Coils are used in devices like transformers, electric motors, and inductors to create a magnetic field when an electric current passes through them. Different winding techniques help optimize the coil’s performance in these devices, ensuring that it meets the required electrical, magnetic, and insulation standards.

Coil winding can be done manually or with automated machines. Automated machines are commonly used for large-scale production as they offer higher precision, speed, and consistency.

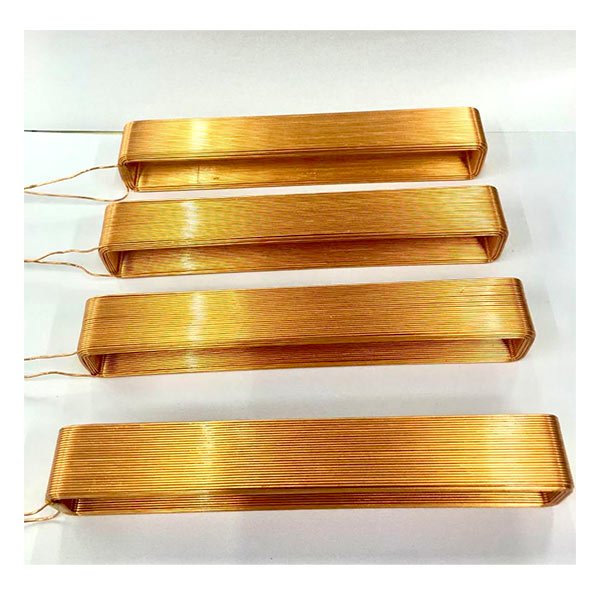

Common Coil Winding Techniques

There are several methods for winding coils, each suited to different types of applications:

1. Wild Coil Winding

In this method, the wire is wrapped irregularly around the core, creating a random pattern. This is fast and cost-effective, making it ideal for mass production of small components like ignition coils and small motors.

2. Helical Coil Winding

Here, the wire is wound evenly in a spiral around the core. This technique is used for low-voltage coils and can include several wires wound at the same time. It’s commonly found in transformers and inductors.

3. Orthocyclic Coil Winding

This technique uses layers that fit neatly into the layers beneath them, maximizing space and creating a strong magnetic field. It’s often used for transformers and electric motors, where efficiency and compactness are important.

4. Sandwich Coil Winding

In sandwich winding, high-voltage windings are placed between low-voltage layers to reduce energy loss. This method is mainly used in transformer production.

5. Bobbin Coil Winding

Bobbin coils are wound around a central bobbin, making them easy to install in devices like power supplies and inductors. The design depends on the specific electrical requirements.

Choosing the Right Winding Method

Choosing the best winding method depends on several factors, such as the device’s size, electrical needs, and the available space for the coil. Engineers carefully consider these factors to ensure the coil performs as required.

Conclusion

Coil winding is crucial in making electrical devices function properly. By choosing the right winding technique, manufacturers can ensure that the coils meet the necessary performance standards. If you need high-quality custom coils for your project, Zhihong Coils can provide expert solutions tailored to your needs. Contact us today to discuss your project or get a quote!

Need a customized coil?

Email us for a quick contact