In the wave of clean energy, wind power generation has gradually become an important part of global renewable energy. In particular, small wind turbines play an irreplaceable role in power supply applications in homes, farms and remote areas due to their convenient installation and controllable costs. In these wind turbines, coils, as one of the core components, directly affect the power generation efficiency and equipment life. Today, we will introduce to you a special coil for small wind turbines that we have recently developed for customers, from the entire process of design to implementation, to demonstrate our superb technical capabilities and customer-oriented service spirit.

Precise design helps customers realize their ideas

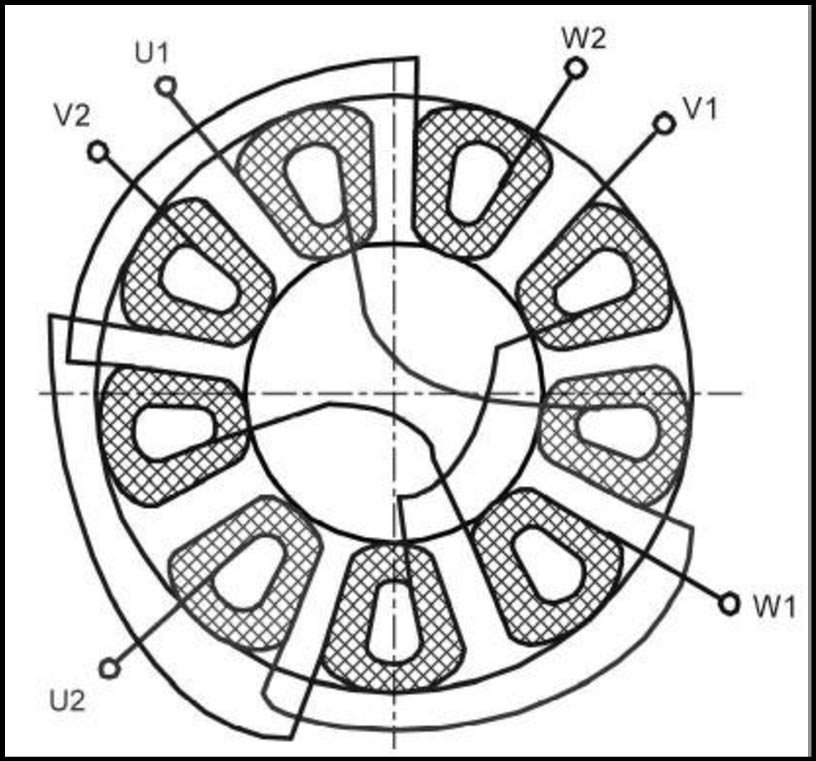

At the beginning, the customer proposed a development requirement to us, hoping to optimize the coil structure of its small wind turbine to improve power generation efficiency and reduce production costs. We communicated with the customer in depth, fully understood its needs, and accurately determined the key dimensions and structure of the coil at the beginning of the design. Through rigorous calculations and multiple rounds of discussions, we helped the customer sort out the design ideas to ensure that the coil has excellent manufacturability while meeting the functional requirements.

3D printing technology makes product implementation more accurate

During the product development process, we used 3D printing technology to make the motor installation model. The application of this technology allows customers to intuitively see the performance of the product in the actual use environment before the sample is produced, and to discover possible problems in advance. The 3D printed installation model not only improves the accuracy of the design, but also greatly shortens the R&D time, laying a solid foundation for subsequent mass production.

Innovative process, improve manufacturing efficiency

In the traditional manufacturing process, the coils originally used by customers need to be connected together by welding. This method not only increases the welding cost, but also poses challenges in process consistency. In order to solve this problem, we have optimized the winding process through innovative design, and successfully achieved seamless connection of the two coils by using a one-time winding method.

This technological breakthrough brings multiple advantages:

1. It eliminates the intermediate welding link, reduces the instability caused by welding, and improves the consistency and reliability of the coil.

2. It reduces the manufacturing cost and saves the extra materials and man-hours required for the welding process.

3. It optimizes the product quality, avoids the risk of breakage caused by the welding point, and makes the product more durable.

Optimize details to reduce volume and cost

In the process of close cooperation with customers, we did not stop at basic winding optimization, but further fine-tuned the size and structure of the coil. Through precise calculations, we reduced the winding volume and space occupancy without affecting the power generation performance. This improvement not only makes the customer’s equipment more compact, but also brings additional cost savings.

In the end, our optimization solution not only successfully reduced material consumption, but also improved the assembly convenience of the product, creating greater economic benefits for customers.

Factory strength ensures high-quality manufacturing

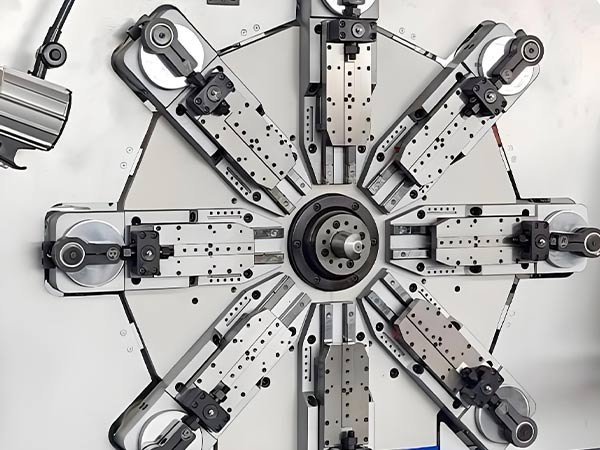

As a company focusing on customized coil development, we have advanced production equipment, mature manufacturing processes and strict quality control systems. The successful implementation of this project fully demonstrates our R&D capabilities, production capabilities and quality control capabilities.

We use fully automated winding equipment to ensure the accuracy and consistency of coil winding; through strict quality inspection processes, we ensure that every coil shipped meets high standards of performance requirements. At the same time, our engineering team is on call at any time to provide customers with one-stop technical support to ensure that they have no worries during use.

Customer first, creating efficient customized services

The success of this coil project not only reflects our excellent technical capabilities, but also demonstrates our customer-centric service concept.

1. In-depth communication throughout the process: From initial conception to finalization, we always maintain close contact with customers to ensure that every link meets customer needs.

2. Quick response and adjustment: In the face of customer feedback, we can make adjustments quickly to improve the flexibility of the project.

3. Cost and efficiency are equally important: While ensuring product performance, we always focus on cost optimization to create the greatest economic value for customers.

Work together to create a better future

The market for small wind turbines is growing rapidly, and technological innovation is the key to improving competitiveness. We look forward to working with more customers with similar needs to jointly promote the development of renewable energy with advanced technology, high-quality products and professional services.

If you are looking for high-quality, small wind turbine coils, or have any customized needs, please feel free to contact us. Let us work together to create a better future for green energy!

Need a customized coil?

Email us for a quick contact