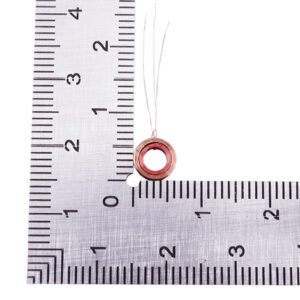

Edgewise coils

Edgewise coils, often referred to as flat copper coil or rectangular coils, are specialized electromagnetic components designed with wires wound in an edge-oriented and stacked configuration. This innovative design not only maximizes space efficiency but also enhances electrical and thermal performance, making these coils ideal for high-density and high-power applications.

Description

- Space-Efficient Design: The edgewise winding technique optimizes the coil’s structure, allowing for compact designs that effectively utilize limited space.

- High Current Handling: With a flat-wire configuration, edgewise coils support higher current densities, reducing resistive losses and improving overall efficiency.

- Enhanced Thermal Performance: The increased surface area of flat wires facilitates superior heat dissipation, ensuring reliable operation even under demanding thermal conditions.

- Durability and Mechanical Stability: The stacked winding design offers robust mechanical strength, making edgewise coils resistant to deformation and external stresses.

Applications

Edgewise coils are versatile components widely utilized across various industries. Their applications include:

- Electric Vehicles (EVs): Supporting compact and efficient powertrain and charging systems.

- Transformers: Key elements in high-performance and space-constrained transformer designs.

- Medical Devices: Enabling reliable and compact solutions for advanced medical equipment.

- Consumer Electronics: Used in high-efficiency devices like wireless chargers and compact power supplies.

Customize by drawing

We can provide customized inductor coils for customers by drawing, and customize the size, shape and characteristics of the coils according to your needs. Provide free coil technology solutions.

Customized on demand

Customized, personalized and reliable inductor coil services tailored to meet the actual needs of customers.

Need a customized coil?

Email us for a quick contact

Relative Product

Solutions

Coils for small Wind Power Generators

In the wave of clean energy, wind power generation has gradually become an important part of global renewable energy. In

Understanding Winding Wire: Types, Characteristics and Applications of Winding Wire

Winding wire is an integral part of modern industrial and electronic equipment. Whether it’s in motors, inductors, transformers, or other

The Essential Guide to Enameled Wire: What It Is, Uses, and Benefits

When it comes to electrical components and manufacturing, few materials are as important as enameled wire. This versatile wire plays