Today, let’s delve into the fascinating world of miniature coil core materials. Core materials have a direct impact on the efficiency, power consumption and stability of coils, so understanding their properties is critical to selecting the right material. In this article, we will explore the unique properties and application areas of amorphous, nanocrystalline, and NdFeB core materials to provide valuable references for the selection of miniature coils.

Amorphous core materials: a combination of flexibility and efficiency

Amorphous materials are characterized by a disordered atomic structure, giving them a unique flexibility. Compared to crystalline materials, amorphous materials have an internal structure that is closer to a “random arrangement”, which gives them good soft magnetic properties in the electromagnetic field. Amorphous core materials can operate efficiently at lower currents, making them suitable for low-power devices. Due to their high permeability over a wide frequency range, amorphous cores are used in a wide range of modern electronic devices, switching power supplies and filters, and are especially advantageous in scenarios where efficiency and low power consumption are important.

Nanocrystalline Core Materials: Balancing Stability and Performance

Nanocrystalline core materials combine the flexibility of amorphous materials with the stability of crystalline structures, an excellent balance of both advantages. Nanocrystalline materials are composed of tiny crystal structures, giving them excellent magnetic properties and high saturation flux density. Nanocrystalline core materials are characterized by low losses and thermal stability, making them particularly suitable for high-frequency power electronics and transformer applications. These properties make them ideal for high-frequency circuits, where they can reduce thermal effects and improve overall system efficiency.

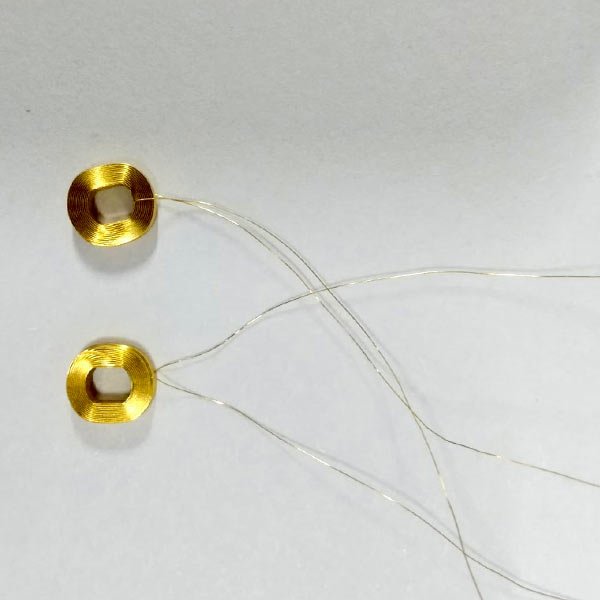

NdFeB Core Materials: Pursuing Ultimate Magnetic Intensity

NdFeB cores, also known as rare-earth magnets, are known for their extremely high magnetic energy product and magnetic strength. Its high remanent magnetization properties mean that it delivers a powerful magnetic force in applications, making it a popular choice in devices such as speakers, headphones and motors. Although NdFeB cores are more costly, their excellent performance makes them indispensable in high-performance audio equipment and precision instruments, especially in applications where strong magnetic fields are required for small size and high efficiency.

Miniature Coil Core Material Selection Guide

After understanding the characteristics of these core materials, we find that choosing the most suitable material depends on the application requirements:

- Amorphous core: suitable for low power consumption and efficiency-oriented application scenarios, such as filters and converters in small electronic devices, which are able to work efficiently at low currents.

- Nanocrystalline cores: Suitable for applications requiring low loss and high thermal stability in high-frequency environments, such as power electronics and high-frequency transformers, ideal for high-frequency devices such as inductors.

- Neodymium-iron-boron cores: excel in applications where high magnetic strength is required, such as high-performance magnetic field devices like speakers, headphones and micro motors.

The choice of core material for miniature coils affects coil performance, power loss and thermal efficiency. Different materials such as amorphous, nanocrystalline, and NdFeB play their part in miniature coils. It is critical for design engineers to understand the properties and applications of these materials, with different combinations adapting to the various innovative needs of the electronics field. Whether for medical devices, sensors, or portable electronics, the right choice of material will provide a solid foundation for project performance enhancement.zhcoils is a professional coil manufacturer, if you have related needs, please feel free to contact us, we will provide you with professional and reliable coil solutions.

Need a customized coil?

Our experts for coils manufacturing will be pleased to advise you!