Transformer coils are vital components in electrical systems, designed to enable efficient energy transfer between circuits. As the heart of the transformer, these coils play a crucial role in adjusting voltage levels to meet various application requirements, from powering industrial equipment to regulating household electricity.

The Basics of Transformer Coils

At their core, transformer coils are conductive windings that facilitate electromagnetic induction. Transformers typically contain two types of coils:

-

Primary Coil: This winding receives the incoming electrical energy and generates a magnetic field within the transformer core.

-

Secondary Coil: Induced by the magnetic field from the primary coil, this winding provides the desired output voltage.

The interaction between these two coils enables the efficient step-up or step-down of voltage, ensuring optimal performance in diverse applications.

Types of Coils Used in Transformers

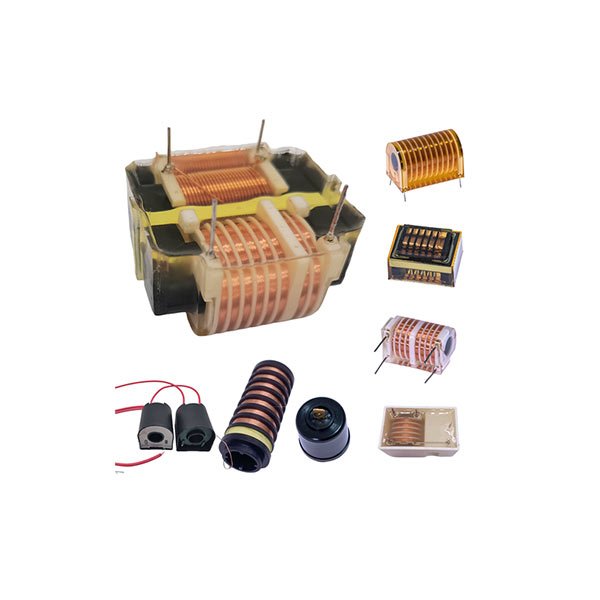

The design and configuration of transformer coils vary to suit different operational needs. Two commonly used shapes include:

Round Coils

Round transformer coils are cylindrical in design and are favored for their robustness and uniform energy distribution. Key attributes include:

Heat Dissipation: Circular shapes allow better cooling, reducing overheating risks.

Durability: Strong mechanical structure resists deformation under stress.

High Voltage Handling: Ideal for heavy-duty applications requiring consistent performance.

Rectangular Coils

Rectangular or layered coils are often used in compact or low-voltage systems. They are characterized by their adaptability and space efficiency. Advantages include:

Custom Configurations: Easily tailored to meet specific spatial requirements.

Compact Design: Suitable for smaller transformers with tight space constraints.

Cost-Effective for Low Voltage: Well-suited for less demanding electrical applications.

Materials Matter: Copper vs. Aluminum

Transformer coil performance is influenced by the materials used in their construction. Two commonly used materials are:

Copper: Known for its excellent conductivity and efficiency, copper coils minimize energy loss and ensure long-term reliability.

Aluminum: Lightweight and cost-effective, aluminum coils are a practical choice for certain applications where budget is a priority.

Applications of Transformer Coils

Transformer coils serve a wide array of industries and uses, including:

Power Grids: Ensuring stable voltage distribution across electrical networks.

Industrial Machinery: Providing energy to large-scale equipment.

Renewable Energy Systems: Adapting energy from solar panels and wind turbines.

Healthcare Equipment: Powering sensitive devices like imaging machines with consistent energy flow.

Why Choose Zhihong Coils for Your Transformer Needs?

At Zhihong Coils, we combine advanced manufacturing processes with a deep understanding of transformer technology to deliver premium-quality coils tailored to your specific needs. Here’s what sets us apart:

Customization: We provide tailored solutions for unique system requirements.

Precision Engineering: Our coils are designed for maximum efficiency and durability.

Versatility: We cater to both high-voltage and low-voltage applications.

Conclusion

Transformer coils are the key to reliable energy transfer and voltage regulation across numerous industries. Understanding their types, materials, and applications can guide better decision-making for your projects. Trust Zhihong Coils to deliver innovative, high-quality solutions for all your transformer coil needs.

Need a customized coil?

Email us for a quick contact